| Multi_R_Designer Quick Guide Manual |

The Start new query panel comprehends two sections. First, the Query index is divided in 11 categorized tabs containing important informations relative to the experimental data while the Search results table contains information on the whereabouts of the data sets fulfilling the search specifications implemented in the Query index. Here are some general facts about this panel.

Two buttons are located at the bottom of the Query panel.

RESET ![]() :

It enables the user to start a new query by resetting all the entries previously

recorded in the 11 categorized tabs. All entries are unselected and

all specified values are removed and replaced by the default ''none''.

:

It enables the user to start a new query by resetting all the entries previously

recorded in the 11 categorized tabs. All entries are unselected and

all specified values are removed and replaced by the default ''none''.

EXECUTE ![]() :

It enables the user to activate the entered specifications and consequently

actualize the Search results listing. It is strongly recommended

that a step-by-step approach be constantly applied in order to avoid that

two or more specifications, which do not contain an intersection,

produce empty Search results. Multi_R_Designer is designed in such

a way that after executing, the available informations are actualized and

presented to the user in various ways.

:

It enables the user to activate the entered specifications and consequently

actualize the Search results listing. It is strongly recommended

that a step-by-step approach be constantly applied in order to avoid that

two or more specifications, which do not contain an intersection,

produce empty Search results. Multi_R_Designer is designed in such

a way that after executing, the available informations are actualized and

presented to the user in various ways.

A query based on the following components can be performed.

FLUIDS: The liquid phase and gas phase compositions are

reported in the integrated databank for each data sets. It enables

the user to search for informations based on the liquid phase composition

or gas phase composition.

ADD (Liquid phase panel): The list of all single liquids, gases and solutes displayed in the integrated databank for the liquid phase composition is presented to the user. The exploration of a specific component in the liquid phase can be done through different approaches.

Name: The component common name, which was extracted directly from the publication, is given.

Synonym/Name: A synonym associated to the component name is given. If not available, the Name is set to complete the field.

Acronym: If available, an acronym associated to the component is given.

Formula: If available, the component chemical formula is given.

ADD (Gas phase panel): The list of all single gases and liquids (at normal conditions) displayed in the integrated databank for the gas phase composition is presented to the user. The exploration of a specific component in the gas phase uses a similar approach than previously mentioned for the liquid phase composition.

aaa

COMPOSITION: After choosing a component in either the liquid phase panel or gas phase panel, the compositions must be set. The compositions were recorded in Multi_R_Designer as they were depicted in the publications. If the composition was given in mol. %, the composition information will be displayed in the appropriate section (mol. %) in Multi_R_Designer. The same concept applies for cases in wt % and vol. %. Note that all the components in the liquid phase must all be expressed in mol. %, or wt % or vol. %. If the units are mixed (i.e. 100% water + 2 mol/L of NaOH or 99 vol. % water + 1 vol. % antifoam + 2 mol/L DEA), the liquid composition will be presented in the mixed section.Multi_R_Designer enables the user to choose one or several gas/liquid compositions simultaneously. However, a double selection can not be achieved in two different tables. Therefore, the mol. %, wt %, vol. % and mixed compositions are combined in the all table enabling the user to choose several compositions at once. Here is a general example on how to use the Fluids tab.

aaa

EXAMPLE:

aa

1) Start a new query.

2) In the Fluids tab, select the Add button in the Liquid phase panel. It contains the list of all components for the liquid phase.

3) Select the Formula option, and enter C4 in the Search entry box. Press OK. It extracts all components for which the chemical formula started with C4.

4) Highlight Diethanolamine and press OK.

5) In the Composition field associated with Diethanolamine, select the (unspecified) pen

. The list of all gas/liquid compositions for cases involving diethanolamine in the liquid phase is presented to the user.

aa

6) Highlight the first and third lines in the mixed table (N.B. select the first line, hold the keyboard Ctrl button and select the third line). Press OK.a) Liquid phase: 1.5 M of diethanolamine in water; Gas phase: 95 mol. % Nitrogen & 5 mol. % Carbon dioxide

b) Liquid phase: 0.05 M of diethanolamine in ethylene glycol; Gas phase: 95 mol. % Nitrogen & 5 mol. % Carbon dioxide

7) Select again the Add button in the liquid panel and highlight Water. Press OK.

Comment: Take note that Water was part of the first line composition (1.5 M of diethanolamine in water) and to avoid any cross-interrogation, this line was removed from the query. However, it can be re-selected with the Choose a composition dialog window for Water.

8) In the Composition field associated with Water, select the (unspecified) pen

. The list of all gas/liquid compositions for cases involving water in the liquid phase is presented to the user.

9) In the all table, highlight the fourth and sixth line (the fourth line corresponds to the gas/liquid composition removed previously). Press OK.

10) Execute. The 3 gas/liquid compositions correspond to a combined 215 data sets from Larachi (1991) and Morsi (1982).

a

PRESSURE (P): The operating pressure was recorded in the integrated databank, when available.

TEMPERATURE (T): The average liquid temperature was recorded in the integrated databank, when available.

LIQUID MASS FLOW RATE (L): The liquid mass flow rate was recorded in the integrated databank, when it is of importance for the measured parameter (i.e. liquid flow rate is irrelevant for static liquid hold-up measurements). Here are some basic relationships between the different liquid flow rate representations (mass flow rate, superficial velocity, volumetric flow rate).

aa

1),

- Liquid superficial velocity (m/s),

- Liquid density (kg/m3)

a2) ,

- Liquid volumetric flow rate (m3/s),

- Column diameter (m)

GAS MASS FLOW RATE (G): The gas mass flow rate was recorded in the integrated databank, when it is of importance for the studied parameter (i.e. gas flow rate is irrelevant for static liquid hold-up measurements). Here are some basic relationships between the different gas flow rate representations (mass flow rate, superficial velocity, volumetric flow rate).

aa

1),

- Gas superficial velocity (m/s),

- Gas density (kg/m3)

a2) ,

- Gas volumetric flow rate (m3/s),

- Column diameter (m)

LIQUID SUPERFICIAL VELOCITY (UL): The liquid superficial velocity was recorded in the integrated databank, a parameter which is closely related to the liquid mass flow rate. Here is a basic relationship between the superficial velocity and interstitial velocity for the liquid phase, which was not recorded in the integrated databank but may come useful in the application of correlations and models.

aa ,

- Liquid interstitial velocity (m/s),

- Dynamic liquid hold-up (m3 dynamic liquid / m3 reactor volume)

GAS SUPERFICIAL VELOCITY (UG): The gas superficial velocity was recorded in the integrated databank, a parameter which is closely related to the gas mass flow rate. Here is a basic relationship between the superficial and interstitial velocity for the gas phase, which was not recorded in the integrated databank but may come useful in the application of correlations and models.

aa ,

- Gas interstitial velocity (m/s), hG - Total gas hold-up (m3 gas / m3 reactor volume),

REACTOR: This tab contains information on the packing

general qualitative characteristics and reactor properties.

PACKING STRUCTURE: (for packed bed reactor only). The packing structure specifies if the reactor is filled with dumped, stacked or structured packing. An appropriate code was recorded in the integrated databank. To have the list of the codes, click with the right button on "packing structure".

PACKING CODE: (for packed bed reactor only). As the packing used in packed bed reactors is defined in a standard classification, it is useful to do a query by selecting a packing in the available list. A more detailed table on packing characteristics is also available by pressing. To each packing type are associated a code, geometric characteristics and operating constants used in models and defined by several authors (Billet, Mackowiak ...). The geometric characteristics are representative of mean values based on informations collected from the literature. Packing of the first, second and third generation are listed. The user may add proprietary packing information in the User tab or complete the lacking data in the available tables and save them. The user can retrieve the original data presented in Multi_R_Designer by pressing Default values button.

These informations related to a packing code is very useful when simulations are carried out. By giving a packing code, the user avoid to introduce other inputs' models associated to this packing such as porosity, bed specific area, etc., and this by using the converter option in the Simulator window.

PACKING TYPE: A packing type was attributed for each data sets based on the informations given by the author. The complete list of packing type encountered in the integrated databank, is given.

PACKING MATERIAL: A packing material was attributed for each data sets based on the information given by the author. The complete list of packing material encountered in the integrated databank is given.

PACKING WETTABILITY: The packing wettability corresponds to the repelling capacity of the packing material on the liquid. It may be considered a hydrophilic (good wettability) or hydrophobic (poor wettability) material. However, it is understood that a wide range of wettability degrees going from highly wettable material to slightly poor and poor wettability was listed amongst materials. For simplicity, the appropriate code between good and poor wettability was recorded in the integrated databank.Examples:

Good wettability: Glass, Catalyst (Al2O3)

Poor wettability: Polypropylene (PP), Glass coated with silicon

PACKING MICROPOROSITY: The packing microporosity defines whether the packing type/material contains internal void. This is mostly the case for catalyst materials. In opposition to the bed porosity (macroporosity), which is defined below, the packing microporosity was not recorded quantitatively. Instead, a code for non microporous packing material or microporous material was included.Examples:

Non microporous: Glass, Metal, Ceramic

Microporous: Activated carbon, Catalyst materials, Benzoic acid

PACKING NOMINAL SIZE: The packing nominal size corresponds mainly to the packing size given by the authors. This is an identification value and not a composite diameter like the effective packing diameter. When the packing has a cylindrical shape, this nominal size corresponds to the cylinder's diameter.

COLUMN TYPE: The column type informs on the structure of the reactor. Even though most reactors are of cylindrical configuration, there are some exceptions in the integrated databank. Some reactors were configured in a rectangular or square shape.

COLUMN DIAMETER (DC): The column diameter is given for all column types. For rectangular and square configurations, an hydraulic column diameter based on the perimeter is accommodated in the databank.

TOTAL BED HEIGHT: The total bed height corresponds to the real height of the bed from top to bottom (Ht).

ACTIVE BED HEIGHT: The active bed height corresponds to the height of a bed section which is specifically used for measuring hydrodynamics, mass transfer or heat transfer parameters. For example, the distance between two conductivity cells incorporated somewhere in the bed to measure the liquid hold-up, liquid axial dispersion or mass transfer coefficients corresponds to the active bed height.

LIQUID DISTRIBUTOR: The liquid distributors defined by the authors present various aspects, making them different from one work to the other. To reduce the exhaustive list, the liquid distributors were combined into significant categories presented below.

- Ejector & Perforated plate (succession of an ejector type distributor followed by a perforated plate)

- Ejector / Injector (ejector or injector type distributor - it usually embraces gas and liquid distribution)

- No liquid distributor (liquid phase is directly introduced to the bed without distribution)

- Perforated plate (liquid is introduced through a perforated plate or device)

- Perforated plate & Pre-packed bed (succession of a perforated plate followed by a shallow packed bed for increasing distribution)

- Point feed (liquid phase is entering the bed through a single hole plate or single tube)

- Pre-packed bed (shallow packed bed preceding the bed test section)

- Tubes / Capillaries & Pre-packed bed (succession of a several tubes like distributor followed by a shallow packed bed)

- Tubes / Capillaries (liquid is introduced via several tubes or capillaries)

GAS DISTRIBUTOR: The gas distributors defined by the authors present various aspects, making them different from one work to the other. To reduce the exhaustive list, the gas distributors were combined into significant categories presented below.

- Ejector / Injector (ejector or injector type distributor - it usually embraces gas and liquid distribution)

- No gas distributor (gas phase is directly introduced to the bed without distribution)

- Perforated plate or tubes (gas is introduced through a perforated plate, tubes or devices)

- Perforated plate & Pre-packed bed (succession of a perforated device followed by a shallow packed bed for increasing distribution)

- Point feed (gas phase is entering the bed through single tube)

- Pre-packed bed (shallow packed bed preceding the bed test section)

- Tubes / Capillaries & Pre-packed bed (succession of a several tubes like distributor followed by a shallow packed bed)

- Tubes / Capillaries / Chimneys (gas is introduced via tubes, capillaries or chimneys)

SOLID: This tab contains quantitative and qualitative

information on the packing physical and thermal properties.

BED POROSITY(epsilon): The bed porosity is defined as the available bed space ratio for gas and liquid flow. It can be represented as:

aa ,

- Total material volume in the bed,

- Total bed volume

GRAIN SPECIFIC AREA (aG): This value represents the packing specific surface area, corresponding hence to the external surface area available on one packing element divided by its own volume.Example: 3 mm diameter cylinder of 5 mm length (d=3 mm; h=5 mm)

aa aa

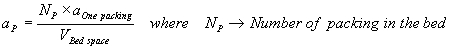

BED SPECIFIC AREA (aP): This value represents the bed specific surface area, corresponding hence to the summation of all packing external surface areas divided by the bed volume. Assuming that every packing element have the same external surface area, the bed specific surface area can be represented as follows:Using the equation defined in the bed porosity section, the following relationship between the grain specific and bed specific surface areas is obtained.

aa

aa

aa aa

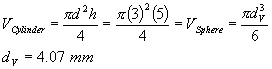

DIAMETER EQUIVALENT TO VOLUME SPHERE (dV): This composite value represents the diameter of a sphere having the same volume of a single packing element.Example: 3 mm diameter cylinder of 5 mm length (d=3 mm; h=5 mm)

Avoiding any exhaustive development, here is a relationship to calculate this composite diameter providing that the bed porosity, the bed specific area and the packing sphericity factor are known.

aa

aaaa

aa aa

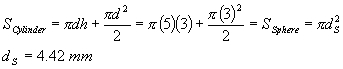

DIAMETER EQUIVALENT TO SURFACE SPHERE (dS): This composite value represents the diameter of a sphere having the same external area of a single packing element.Example: 3 mm diameter cylinder of 5 mm length (d=3 mm; h=5 mm)

Avoiding any exhaustive development, here is a relationship to calculate this composite diameter providing that the bed porosity, the bed specific surface area and the packing sphericity factor are known.

aa

aa

aa aa

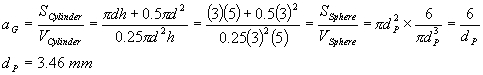

EFFECTIVE PARTICLE DIAMETER (dP): This composite value represents the diameter of a sphere having the same specific external area of a single packing element.Example: 3 mm diameter cylinder of 5 mm length (d=3 mm; h=5 mm)

From the equation above, a simple relationship between this composite diameter, the bed porosity and bed specific surface area is proposed.

aa

aa

aa

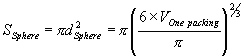

SPHERICITY FACTOR (phi): The packing sphericity factor corresponds to the ratio of the surface area of the sphere having the same volume as a particle to the actual surface area of the packing. When unknown, the sphericity factor can be calculated if the bed porosity, the bed specific surface area (aP) and the number of packing units per bed volume (NP) are known.aa

aa

aa

aaaa

NUMBER OF PACKING UNITS PER BED VOLUME (NP): When available, the number of packing units dumped in the reactor per bed volume is recorded to the integrated databank.

SOLID THERMAL CONDUCTIVITY: For cases involving heat transfer experiments, the packing material thermal conductivity was added to the integrated databank when given by the author. Otherwise, this parameter was determined by the Multi_R_Designer team using other considerations.

SOLID HEAT CAPACITY: For cases involving heat transfer experiments, the packing material heat capacity is recorded in the integrated databank when given by the author. Otherwise, the value was determined by the Multi_R_Designer team using other considerations.

SOLID VOLUMETRIC THERMAL EXPANSION: For cases involving heat transfer experiments, the packing material volumetric thermal expansion is recorded in the integrated databank when given by the author. Otherwise, the value was determined by the Multi_R_Designer team using other considerations.

LIQUID: This tab contains quantitative and qualitative

information on the liquid phase physical and thermal properties.

LIQUID DENSITY: The liquid phase density given by the author or approximated by the Multi_R_Designer team is recorded in the integrated databank when accessible.

LIQUID VISCOSITY: The liquid phase viscosity given by the author or approximated by the Multi_R_Designer team is recorded in the integrated databank when accessible.

LIQUID SURFACE TENSION: The liquid surface tension given by the author or approximated by the Multi_R_Designer team is recorded in the integrated databank when accessible.

LIQUID DIFFUSION COEFFICIENT: The solutes diffusion coefficient in the liquid phase is recorded in the integrated databank when accessible for gas-to-liquid or solid-to-liquid mass transfer experiments exclusively.

FOAMING PROPERTY: The foaming property of the liquid is included in the databank. The user has the choice between coalescent (ex: water) and foaming (ex: water + isopropanol). Foaming is considered in the integrated databank for cases when the liquid at least produces slight foaming conditions.

FLOW CONSISTENCY INDEX (K): When given by the author, the flow consistency index, which is related to non-Newtonian liquids was included in the integrated databank. This value along with the flow behavior index (n) were used to calculate the effective liquid viscosity based on the power law model of Ostwald-de-Waale.

aa ,

- Effective shear rate (1/s)

FLOW BEHAVIOR INDEX (n): When given by the author, the flow behavior index which is related to non-Newtonian liquids was included in the integrated databank (see Flow consistency index definition).

LIQUID THERMAL CONDUCTIVITY: The liquid thermal conductivity given by the author or determined by the Multi_R_Designer team based on other considerations is recorded in the databank for cases involving heat transfer experiments exclusively.

LIQUID HEAT CAPACITY: The liquid heat capacity given by the author or determined by the Multi_R_Designer team based on other considerations is recorded in the databank for cases involving heat transfer experiments exclusively.

LIQUID THERMAL DIFFUSIVITY: The liquid thermal diffusivity given by the author or determined by the Multi_R_Designer team based on other considerations is recorded in the databank for cases involving heat transfer experiments exclusively.

GAS: This tab contains quantitative and qualitative information

on the gas phase physical and thermal properties.

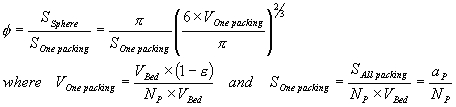

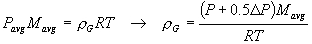

GAS DENSITY (rhoG): The gas phase density given by the author or approximated by Multi_R_Designer is recorded in the integrated databank. For low pressure operation, the gas density is approximated with the ideal gas law, if the gas composition is known. Moreover, if the total pressure drop is measured, an average pressure operation can be assumed, an the gas density can be calculated as follows:The operating pressure (P) is usually considered as the exit pressure at the bottom of the bed. At the entrance, the gas is compressed to P + DP and therefore the average pressure can be assumed as the operating pressure + half of the total pressure drop.

aa

aaExample: Air density at 1 atm and 300 K with a total pressure drop of 10000 Pa/m (Bed length: 1.5 m)

aa aa

GAS VISCOSITY: The gas phase viscosity given by the author or approximated by the Multi_R_Designer team is recorded in the integrated databank.

GAS DIFFUSION COEFFICIENT: The gas phase diffusion coefficient which is given by the author or approximated by the Multi_R_Designer team based on other considerations is recorded in the integrated databank for cases involving gas-to-liquid mass transfer experiments exclusively.

GAS THERMAL CONDUCTIVITY: The gas phase thermal conductivity which is given by the author or approximated by the Multi_R_Designer team based on other considerations is recorded in the integrated databank for cases involving heat transfer experiments exclusively.

GAS HEAT CAPACITY: The gas phase heat capacity which is given by the author or approximated by Multi_R_Designer is recorded in the integrated databank for cases involving exclusively heat transfer experiments.

SATURATED GAS HEAT CAPACITY: The gas phase heat capacity at saturation which is given by the author or approximated by the Multi_R_Designer team is recorded in the integrated databank for cases involving heat transfer experiments exclusively.

GAS VOLUMETRIC THERMAL EXPANSION: The gas phase volumetric thermal expansion given by the author or approximated by the Multi_R_Designer team is recorded in the integrated databank for cases involving heat transfer experiments exclusively.

GAS THERMAL DIFFUSIVITY: The gas phase thermal diffusivity which is given by the author or approximated by the Multi_R_Designer team is recorded in the integrated databank for cases involving heat transfer experiments exclusively.

HYDRODYNAMICS: It contains parameters as well as technical

information about reactors' hydrodynamics. These parameters concern the

flow regime, pressure drop, liquid hold-up and liquid axial dispersion

measurements. A query can be executed on the following aspects.

FLOW REGIME (for packed bed reactors): The gas/liquid flow interaction in packed bed reactor can be generally defined in terms of : preloading zone, loading point, loading zone, flooding point, flooding zone, dry conditions, static gas liquid flow only and static liquid wet conditions.

GENERAL FLOW REGIME (for trickle beds) : It classifies the operating flow regime in Low interaction, High interaction and the Transition between them.

SPECIFIC FLOW REGIME (for trickle beds and flooded beds) : It classifies the gas/liquid flow interaction into more specific categories, which are either part of the LIR or the HIR. Here are the flow regimes listed in the integrated databank.Low interaction regime: Ripple flow, Trickle flow (for trickle bed reactors only). High interaction regime: Pulsing flow, Bubble flow, Dispersed bubble flow, Large bubble flow, Foaming flow, Spray flow, Transition churn/bubble flow, Churn flow, Base flow outside the pulses, Transition trickle/pulsing flow, Transition trickle/bubble flow, Transition trickle/spray flow, Transition pulsing/bubble flow, Transition pulsing/dispersed bubble flow, Transition pulsing/spray flow, Transition bubble/dispersed bubble flow, Transition churn/spray flow, Foaming pulsing flow, Transition trickle/foaming pulsing flow, Stagnant gas trickle flow Transition LIR/HIR regime: Transition trickle/pulsing flow

L AT TRICKLE/PULSING TRANSITION FLOW: (for trickle bed reactors). The liquid mass flow rate can be used as the measured variable for cases involving trickle-to-pulsing transition experiments. Some correlations from the literature calculates the liquid superficial velocity at the trickle-to-pulsing transition for a set of operating conditions, including the gas mass flow rate.

G AT TRICKLE/PULSING TRANSITION FLOW: (for trickle bed reactors). Similarly to the previous definition, the gas mass flow rate can be used as the measured variable for the trickle/pulsing transition. Most correlations from the literature calculates the gas superficial velocity at the trickle-to-pulsing transition for a set of operating conditions, including the liquid mass flow rate.

G AT LOADING POINT: (for packed bed reactors). The gas mass flow rate can be used as the measured variable for cases involving the loading point flow regime experiments. Some correlations from the literature calculates the gas superficial velocity at the loading point for a set of operating conditions, including the liquid mass flow rate.

G AT FLOODING POINT: (for packed bed reactors). Similarly to the loading point definition, the gas mass flow rate can be used as the measured variable in the flooding point flow regime experiments. Some correlations from the literature calculates the gas superficial velocity at the flooding point for a set of operating conditions, including the liquid mass flow rate.

PRESSURE DROP: Pressure drop measurements give a legitimate outlook of the energy consumption encountered in various conditions. Different pressure drop classifications are represented in the query.For trickle bed and Flooded bed reactors :

For packed bed reactors :

TOTAL PRESSURE DROP (deltaPT): It defines the differential pressure drop between the top and bottom of the bed, which basically refers to the total energy loss.

GRAVITATIONAL PRESSURE DROP (deltaPG): It is a component of the total pressure drop, which depends on the gas/liquid (liquid hold-up - hT) gravitational weight. The gravitational pressure drop vector is opposing the frictional pressure drop vector in concurrent downflow operation, which could result in a negative total pressure drop if the tower is operated a low gas and high liquid flow rates. The gravitational pressure drop is not directly measurable, so an equation related to the total liquid hold-up is used for its calculation.

aa aa

FRICTIONAL PRESSURE DROP (deltaPF): It is a component of the total pressure drop, which depends mostly of the frictional interaction between the gas/liquid/solid phases (gas/solid interaction + liquid/solid interaction +/- gas/liquid interaction). Knowing the total liquid hold-up and gravitational pressure drop, the frictional pressure drop can be calculated.

aa aa

DRY PRESSURE DROP : It defines the differential pressure drop between the top and bottom of the bed in the dry conditions, which basically refers to the total energy loss by the gas phase flowing through the dry packing.

IRRIGATED PRESSURE DROP : Equivalent to the total pressure drop defined above.

PRESSURE MEASUREMENT TECHNIQUE: Pressure drop measurements can be acquired in various ways. Here are the techniques listed in the integrated databank.

aa

- Differential pressure sensors

- Differential U-tube manometer

- Pressure sensors

- Pressure sensors 'Bourdon'

- Pressure transducers

- U-tube manometer

ERGUN CONSTANT E1: The Ergun constants (E1 and E2) are extracted from pressure drop measurements in dry conditions across a bed filled with a particular packing element. The fitting of these experimental values can be achieved via the parabolic Ergun equation. Knowing the bed porosity, the effective packing diameter (dP), the gas viscosity and gas density, the constants E1 and E2 can be easily extracted with a diagram corresponding to the specific pressure drop in function of the gas superficial velocity (UG).

aa aa

ERGUN CONSTANT E2: See Ergun constant E1 for explanations.

aa

LIQUID HOLD-UP: The liquid hold-up corresponds to the liquid volume occupation in the bed enclosure divided by the total bed volume. In other word, it corresponds to the fraction of liquid occupation in the bed during reactor operation.

STATIC LIQUID HOLDUP (hS): It is a component of the total liquid hold-up, which depends mostly on the packing capillarity action and the liquid surface tension. After operation and a lengthy draining procedure, the liquid volume remaining in the bed interstice is referred as the extra-granular static liquid holdup.

DYNAMIC LIQUID HOLDUP (hD): It is a component of the total liquid hold-up, which depends mostly of the frictional interactions between the gas/liquid/solid phases. This parameter corresponds to the liquid volume drained out of the bed after the operation was stopped.

TOTAL LIQUID HOLDUP (hT): This value corresponds to the summation of the static and dynamic liquid holdups.

aa aa

LIQUID HOLDUP MEASUREMENT TECHNIQUE: Different techniques were used to measure liquid hold-up. Here is the list of the techniques listed in the integrated databank.

- Conductance probes (RTD) (RTD curves were obtained with conductance probes and liquid hold-up extracted from the RTD curve)

- Conductivity cells (RTD) (RTD curves were obtained with conductivity cells and liquid hold-up extracted from the RTD curve)

- Draining

- Draining for dynamic / RTD for total liquid holdup

- Draining for dynamic / Weighting for total liquid holdup

- Tensiometric method

- Weighting

- Coloring agent

- X-Ray fluoresence

- UV spectrophotometer

LIQUID AXIAL DISPERSION: The liquid axial dispersion defines the capacity of the liquid to disperse itself axially across the bed for better mass transfer or heat transfer conditions.

LIQUID AXIAL DISPERSION COEFFICIENT: The liquid axial dispersion coefficient is obtained from the fitting of partial differential equations on Residence Time Distribution (RTD) curves.

LIQUID AXIAL DISPERSION MEASUREMENT TECHNIQUE: Different techniques were used to measure the liquid axial dispersion coefficient. Here is the list of the techniques listed in the integrated databank. All techniques produce RTD curves which are used to extract the liquid axial dispersion coefficient.

aa

- Colorimetric photometer

- Conductivity cells

- Refractometer

- UV spectrophotometer

- X-ray fluorescence analyser

RTD MODEL: It informs on the partial differential equations used to fit the residence time distribution (RTD) curve, so to extract the liquid axial dispersion coefficient.

aaa

- PDE-Transient diffusion model

- Piston-Dispersion (PD) model

- Piston-Dispersion-Exchange (PDE) model

MASS TRANSFER: This tab contains parameters as well as

technical informations about mass transfer characteristics. The parameters

included in the databank concern the gas/liquid contact area, solid/liquid

contact area, gas/liquid mass transfer coefficients and solid/liquid mass

transfer coefficients. A query can be executed on the following aspects.

GAS-TO-LIQUID CONTACT AREA

LG INTERFACIAL AREA (aLG): This parameter defines the total contact area between the gas phase and liquid phase during operation. Larger gas/liquid contact area usually promotes better mass transfer potential.

FRACTION OF WETTED AREA (fLG): It corresponds to the gas/liquid interfacial area (aLG) divided by the bed specific surface area.

aa aa

SOLID-TO-LIQUID CONTACT AREA

LS INTERFACIAL AREA (aLS):This parameter defines the total contact area between the solid phase and liquid phase during operation.

WETTING EFFICIENCY (phiLS): It corresponds to the solid/liquid interfacial area (aLS) divided by the bed specific surface area.

aa

GAS-TO-LIQUID MASS TRANSFER COEFFICIENTS

GAS-SIDE VOLUMETRIC MASS TRANSFER COEFFICIENT (kGaLG): This parameter defines quantitatively the mass transfer efficiency between the liquid phase and gas phase. This coefficient relies solely on the mass transfer resistance encountered in the gas film (two film theory).Example: air humidification or pure liquid stripping

LIQUID-SIDE VOLUMETRIC MASS TRANSFER COEFFICIENT (kLaLG): This parameter defines quantitatively the mass transfer efficiency between the liquid phase and gas phase. This coefficient relies solely on the mass transfer resistance encountered in the liquid film (two-film theory).Example: oxygen absorption in water or pure gas absorption in water

GLOBAL GAS-SIDE VOLUMETRIC MASS TRANSFER COEFFICIENT (KGaLG): This parameter defines quantitatively the mass transfer efficiency between the liquid phase and gas phase. This coefficient relies mostly on the mass transfer resistance encountered in the gas film but also depends on the resistance in the liquid film. The overall gas-film volumetric mass transfer coefficient is related to kGaLG and kLaLG using the two film theory.

aa where m is known as the partition coefficient

Example: CO2 absorption from air into light NaOH aqueous solution

HETP : Packed height equivalent to a theoretical (equilibrium) plate (stage) is defined by the total packed height to the number of equivalent equilibrium stages ratio: Ht / Nt.

HTUOG : The overall height of a transfer unit based on the gas phase defined by :

where G is the gas mass flow rate.

HTUOL : The overall height of a transfer unit based on the liquid phase defined by :where L is the gas mass flow rate.

Remark: HETP = HTU (OL or OG) when the operating and equilibrium lines are straight and parallel.

SOLID-TO-LIQUID MASS TRANSFER COEFFICIENTS

VOLUMETRIC MASS TRANSFER COEFFICIENT ON PARTICLE (kLSaLS- Particle): This parameter defines quantitatively the mass transfer efficiency between the liquid phase and the reacting solid phase at the particle. This coefficient relies solely on the mass transfer resistance encountered in the liquid phase.

MASS TRANSFER COEFFICIENT ON PARTIALLY WETTED PARTICLE (kLSphiLS- Particle): This parameter defines qualitatively the mass transfer efficiency between the liquid phase and the reacting solid phase based on the wetted fraction of the particle. Here is the relationship between kLSaLS-Particle and kLSphiLS-Particle.

aa aa

MASS TRANSFER COEFFICIENT ON PARTICLE (kLS- Particle): This parameter defines qualitatively the mass transfer efficiency between the liquid phase and the reacting solid phase at the particle. This coefficient corresponds roughly to the transferring velocity of molecules into the liquid phase. This parameter can be obtained only if the wetting efficiency (phiLS) for the same experiment is also known.VOLUMETRIC MASS TRANSFER COEFFICIENT AT REACTOR'S WALL (kLSaLS-Reactor's wall): This parameter defines quantitatively the solid-to-liquid mass transfer potential at the reactor's wall.

MASS TRANSFER COEFFICIENT FOR PARTIALLY WETTED PARTICLES AT REACTOR'S WALL (kLSphiLS-Reactor's wall): This parameter defines qualitatively the solid-liquid mass transfer potential at the reactor's wall based on the wetted fraction of the packing. Here is the relationship between kLSaLS-Reactor's wall and kLSphiLS-Reactor's wall.

aa aa

MASS TRANSFER COEFFICIENT AT THE REACTOR'S WALL (kLS-Reactor's wall): This parameter defines qualitatively the solid-liquid mass transfer potential at the reactor's wall. This parameter can be obtained only if the wetting efficiency (phiLS) for the same experiment is also known

EXPERIMENTAL TECHNIQUE: For experiments dealing with mass transfer operations, this option offers a general overview of the techniques used to obtain the measured parameter. Here is a list of repertoried experimental approaches to measure contact areas and mass transfer coefficients

- Adsorption

- Chemical absorption

- Hydrodemetallization

- Physical absorption

- Physical desorption

- SL mass transfer by dissolution

- SL mass transfer by electrochemical method

- SL mass transfer by hydrogenation

- SL mass transfer by ion-exchange reaction

- Wetting efficiency by physical method

HEAT TRANSFER: This tab contains parameters about trickle-bed

and flooded-bed reactors heat transfer characteristics. A query can be

done on the following variables.

WALL HEAT TRANSFER COEFFICIENT: This parameter corresponds to the heat transfer coefficient obtained across the reactor's wall.

PARTICLE-TO-FLUID HEAT TRANSFER COEFFICIENT: This parameter corresponds to the heat transfer coefficient obtained between the particles (solid phase) and the fluid (which consists mainly of the liquid phase).

RADIAL EFFECTIVE THERMAL CONDUCTIVITY: It corresponds to the effective heat conductivity in the three phase system (gas/liquid/solid) obtained in the radial direction.

REFERENCE: This tab enables the user to search for specific

publications from the literature based on the authors and/or keywords,

which were implemented by the Multi_R_Designer team based on the publication

groundwork. Here is a general example

on how to use the Reference tab.

EXAMPLE:1) Start a new query

.

2) In the Reference tab, check the box corresponding to Author. The user can decide to search for two or more authors collaborating on the same publication (AND option in the Mode field) or search for two or more authors independently (OR option in the Mode field).

3) Select AND in the Mode field, and write Iliuta + Thyrion in the Value field (+ demarcates 2 separate authors or keywords). Do not allow any empty space between the words and the plus sign (+). Execute.

4) Two publications for which Iliuta and Thyrion have collaborated are found in the integrated databank.

5) Activate the Reset

button.

6) Redo the same procedure while choosing OR in the Mode field. Execute again.

7) One more publication is extracted from the databank. The same aspects apply for a keywords query.

SEARCH RESULTS:

The Search results table contains information on the whereabouts of the experimental data sets extracted from a query.

N Pts: It gives the number of data sets in the publication which fulfill the query specifications (By clicking on the N Pts heading, the publications will be sorted in an increasing or decreasing order based on the number of points).Author: It gives the publication author(s) (By clicking on the Author heading, the publications will be sorted in alphabetical order based on the first author).

Year: It gives the year of publication of the thesis, article or private communication (By clicking on the Year heading, the publications will be sorted in an increasing or decreasing order based on the year of publication).

Details: By selecting the Details

button, the user will obtain the complete publication reference (see Show reference list).

The corresponding boxes associated to the publications are selected

by default. If the user deselects one or several publications, the corresponding

data sets will not be included in any subsequent diagram.

This section gives details on the publications from which experimental measurements were extracted and incorporated in the integrated databank. A total of 144 publications, either thesis, articles or private communications, were reported in Multi_R_Designer. Here is an overview of the information available on the these publications.

Publication #: For logistic reasons, a number is given for each publication. Multi_R_Designer often refers the publications with their numbers (By clicking on the Publication # heading, the publications will be sorted in alphabetical order based on their number).

aa

Author: It gives the publication author(s) (By clicking on the Author heading, the publications will be sorted in alphabetical order based on the first author).

aa

Year: It gives the year of publication of the thesis, article or private communication (By clicking on the Year heading, the publications will be sorted in an increasing or decreasing order based on the year of publication).

aa

Details: By selecting the Detailsbutton associated to the publication, the following information will be presented to the user.

These informations can be printed or exported as a .html file.

- Author

- Title

- Publication

- Year

- Volume (Number) (optional)

- Pages (optional)

- Additional references (optional) (Additional references informs on quoted publications, which are important for the understanding of the actual publication)

- Keywords (Multi_R_Designer team implemented keywords based on the publication groundwork)

This option enables the user to create or to open a database which contains proprietary (experimental) data saved under the same format as the integrated Multi_R_Designer databank. This becomes useful when different comparisons in the query index with the integrated databank is desired and for cases requiring automatic simulations. The user database with * .data extension can hold more than one data set introduced independently. Any subsequent study (query or simulation) can be achieved using one or several data sets. A simulated data file, associated to the user database, is automatically created with *.sim extension when an automatic simulation is carried over.

| Multi_R_Designer Quick Guide Manual |